Advanced Smart Alloys Transforming Zinc Die Casting Performance

We’re developing advanced smart alloys that are revolutionizing zinc die casting capabilities, moving beyond traditional formulations to deliver enhanced performance characteristics. These next-generation zinc alloys incorporate micro-additions of elements like nickel, copper, and titanium, creating materials with improved strength, corrosion resistance, and thermal stability. Our nickel-enhanced zinc die casting alloys achieve tensile strengths up to 320 MPa—20% higher than standard Zamak alloys—while maintaining excellent castability for thin-wall components.

Smart zinc alloys with controlled grain structures exhibit superior fatigue resistance, making them suitable for dynamic automotive applications like door latch mechanisms and seat adjusters. We’ve also engineered corrosion-resistant zinc die casting alloys that eliminate the need for protective coatings in moderate environments, reducing production steps and environmental impact. These smart alloys retain zinc’s inherent advantages—excellent fluidity and cost efficiency—while addressing historical limitations, expanding zinc die casting applications into previously restricted high-performance areas.

Real-Time Process Monitoring in Industry 4.0 Zinc Die Casting

Industry 4.0 integration has introduced real-time process monitoring that optimizes zinc die casting operations for efficiency and quality. We’ve equipped our zinc die casting cells with an array of sensors that track temperature, pressure, flow rate, and die position at millisecond intervals. This data feeds into centralized control systems that identify process deviations before they affect part quality, reducing scrap rates by 35% in high-volume production.

AI-powered algorithms analyze the streaming data to predict optimal process parameters, automatically adjusting injection speeds and pressure profiles for different zinc die casting geometries. For complex components, the system can detect potential filling issues and modify parameters mid-cycle to ensure complete cavity fill. Operators receive instant alerts through interactive dashboards, enabling proactive intervention rather than reactive problem-solving. This real-time monitoring transforms zinc die casting from a traditionally experience-based process to a data-driven operation with unprecedented consistency and efficiency.

Digital Twin Technology for Zinc Die Casting Optimization

Digital twin technology is revolutionizing zinc die casting development and production, creating virtual replicas that mirror physical processes for optimization. We build detailed digital twins of our zinc die casting machines, dies, and alloy behavior, allowing us to simulate production runs before physical implementation. This virtual testing enables us to optimize gating designs, cooling profiles, and cycle parameters for new zinc die casting components without risking expensive tooling or material waste.

The digital twin continuously synchronizes with real-time production data, creating a feedback loop that refines simulations based on actual performance. For existing zinc die casting processes, the digital twin identifies subtle inefficiencies—like uneven die heating or suboptimal injection timing—that human operators might miss. We’ve reduced new product development time by 40% using digital twins to validate zinc die casting designs upfront, and production optimization through virtual testing has increased overall equipment effectiveness (OEE) by 25%.

Sustainable Innovations in Smart Zinc Die Casting Processes

Sustainability innovations in smart zinc die casting processes align with Industry 4.0 goals of resource efficiency and environmental responsibility. Our energy-smart zinc die casting machines incorporate regenerative drives that recover energy during deceleration, reducing power consumption by 18–22% per cycle. We’ve developed closed-loop recycling systems that integrate with process monitoring, automatically diverting off-spec zinc die casting components to recycling stations and adjusting formulations to utilize reclaimed material.

Smart lubrication systems precisely meter environmentally friendly, water-based lubricants only where needed, reducing consumption by 60% compared to traditional spray systems. AI algorithms optimize production schedules to minimize energy-intensive heating and cooling cycles during changeovers between zinc die casting runs. These sustainable innovations, enabled by Industry 4.0 connectivity, have reduced the carbon footprint of our zinc die casting operations by 30% while maintaining productivity and part quality.

Predictive Maintenance in Industry 4.0 Zinc Die Casting

Predictive maintenance, enabled by Industry 4.0 integration, has transformed equipment reliability in zinc die casting operations. We’ve implemented vibration, acoustic, and thermal sensors on critical components of zinc die casting machines—including plungers, hydraulic systems, and furnace. Machine learning models analyze sensor data to identify early signs of wear or potential failure, creating maintenance schedules based on actual equipment condition rather than fixed time intervals.

This approach has reduced unplanned downtime in our zinc die casting facilities by 50%, as maintenance is performed only when needed and during scheduled production breaks. For example, the system can predict plunger wear in zinc die casting machines weeks before failure, allowing for replacement during planned maintenance windows. The predictive system also optimizes die maintenance, identifying when surface degradation might affect zinc die casting quality and scheduling refinishing before defects occur. This proactive approach extends equipment life while ensuring consistent zinc die casting performance.

Smart Alloy-Process Integration in Modern Zinc Die Casting

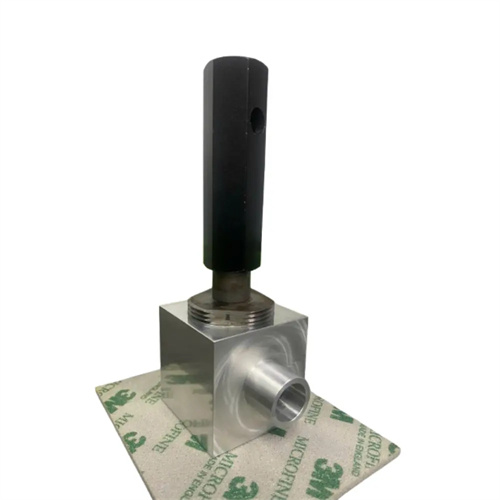

The integration of smart alloys with Industry 4.0 processes creates a synergistic system that maximizes zinc die casting capabilities. We’ve developed alloy-specific process parameters stored in our digital manufacturing execution system, which automatically configures machine settings when switching between zinc die casting alloys. This ensures optimal processing for each smart alloy’s unique characteristics, from melting temperatures to injection profiles.

Real-time quality monitoring systems, calibrated for each smart alloy, perform inline inspections using machine vision and spectroscopy, verifying both dimensional accuracy and material composition in zinc die casting components. This integration allows us to trace each component back to its alloy batch and process parameters, creating complete digital threads for quality assurance. The combination of smart alloys and Industry 4.0 integration has expanded zinc die casting applications into precision-critical sectors like medical devices and aerospace, where material consistency and process traceability are paramount.