The Science Behind Zinc Die Casting’s Exceptional Fluidity

Zinc die casting’s superior fluidity stems from unique material properties that make it ideal for overcoming complex design challenges. At its melting point (380–420°C), zinc alloys exhibit significantly lower viscosity than aluminum or magnesium, allowing molten material to flow through intricate die cavities with minimal resistance. This fluidity is enhanced by zinc’s favorable thermal conductivity, which maintains consistent temperature throughout the casting process, preventing premature solidification in thin sections or narrow passages.

We’ve studied how alloy composition influences fluidity, finding that controlled additions of aluminum and copper in zinc die casting alloys optimize flow characteristics without compromising mechanical properties. The material’s ability to maintain fluidity even as it cools enables complete filling of complex geometries that would trap air or create voids with less fluid materials. This scientific advantage forms the foundation for zinc die casting’s ability to overcome design challenges that stymie other manufacturing processes.

Resolving Thin-Wall Design Challenges with Zinc Die Casting

Zinc die casting’s superior fluidity resolves critical thin-wall design challenges that limit other manufacturing methods. We regularly produce components with wall thicknesses as low as 0.5 mm—sections that would be impossible to fill consistently with aluminum or magnesium alloys. This capability allows designers to create lightweight, compact parts without sacrificing structural integrity, addressing the ongoing demand for miniaturization in electronics and automotive systems.

The fluidity of zinc die casting ensures uniform material distribution even in extremely thin sections, preventing the cold shuts and incomplete fills common in other die casting processes. We’ve successfully produced intricate heat sinks with thin fins (0.6 mm thick) for electronics cooling, where aluminum would require thicker walls to ensure complete filling. For automotive sensor housings with thin-walled protective sleeves, zinc die casting maintains dimensional accuracy across thousands of production units, demonstrating its reliability in resolving thin-wall design challenges.

Overcoming Geometric Complexity with Zinc Die Casting Flow

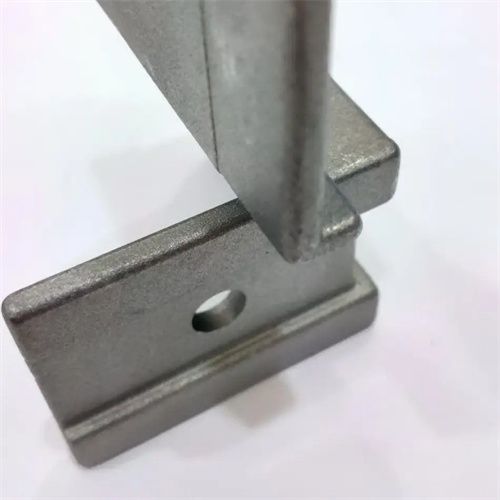

Zinc die casting’s exceptional fluidity enables us to overcome geometric complexity challenges that would be cost-prohibitive or impossible with other methods. The material flows easily around sharp corners, through narrow channels, and into intricate details, capturing complex geometries in a single manufacturing step. We’ve eliminated assembly requirements by integrating multiple features—threads, mounting bosses, and internal passages—into single zinc die casting components that would otherwise require three or more assembled parts.

For example, zinc die casting produces complex automotive door latch mechanisms with integrated linkages and spring seats that would require precision machining and assembly if made from steel. In consumer electronics, we create housing components with intricate decorative patterns and functional ribs in thin sections, all formed in one casting operation. This ability to consolidate complex geometries reduces part counts, simplifies supply chains, and improves overall component reliability—all made possible by zinc die casting’s superior fluidity.

Eliminating Porosity and Void Challenges in Zinc Die Casting

Zinc die casting’s superior fluidity helps eliminate porosity and void challenges that compromise part integrity in other manufacturing processes. The material’s ability to flow smoothly into die cavities minimizes turbulence, reducing the entrapment of air that causes porosity in cast components. We achieve near-net-shape density in critical areas, eliminating the need for secondary operations like impregnation that add cost and complexity.

The controlled flow enabled by zinc die casting’s fluidity allows for sequential filling of complex cavities, pushing air ahead of the molten metal toward strategically placed vents. This prevents the formation of trapped gas pockets in thick-to-thin transitions and deep recesses—common problem areas in less fluid materials. We’ve verified through ultrasonic testing that zinc die casting components exhibit less than 1% porosity by volume, meeting the strict requirements for pressure-tight automotive components and hermetically sealed electronics enclosures.

Addressing Tolerance and Consistency Challenges with Zinc Die Casting

Zinc die casting’s superior fluidity addresses tolerance and consistency challenges that plague high-volume production of complex components. The material’s uniform flow and rapid solidification create consistent microstructures across production runs, minimizing dimensional variation. We consistently achieve tolerances of ±0.02 mm for critical features, even in complex geometries, ensuring proper fit in assemblies without the need for selective fitting or post-casting machining.

The predictable flow behavior of zinc die casting allows for precise simulation of filling patterns during design validation, enabling upfront optimization of gating and venting. This predictability translates to exceptional consistency across production batches—we’ve measured part-to-part dimensional variation below 0.015 mm for high-volume zinc die casting components. For automotive and electronics manufacturers requiring interchangeable parts across global production facilities, this consistency eliminates the tolerance stack-up challenges that complicate assembly of components made with less predictable processes.

Enhancing Design Freedom Through Zinc Die Casting Fluidity

Zinc die casting’s superior fluidity enhances design freedom by removing traditional manufacturing constraints that limit innovation. Designers are no longer forced to simplify geometries to accommodate manufacturing limitations—instead, they can optimize for performance, weight, and functionality while relying on zinc die casting to deliver the required shapes. This freedom has enabled breakthrough designs in medical devices, where complex internal channels for fluid flow are now possible in lightweight zinc die casting components.

In automotive lighting systems, zinc die casting’s fluidity captures the intricate reflector geometries needed for advanced optical performance, eliminating the need for post-casting machining of critical surfaces. For wearable electronics, designers create ergonomic shapes with integrated features that enhance user comfort, all produced in a single zinc die casting operation. By overcoming manufacturing limitations through superior fluidity, zinc die casting empowers designers to push boundaries and create more innovative, functional products.