Material Properties Comparison: Zinc Die Casting vs. Aluminum

Understanding material properties is critical when choosing between zinc die casting and aluminum for your application. Zinc die casting alloys offer higher strength-to-weight ratios in smaller cross-sections, with tensile strengths ranging from 200–300 MPa and excellent impact resistance. Zinc’s lower melting point (380–420°C) compared to aluminum (660°C) enables more precise casting of fine details and thinner walls (0.5–2 mm).

Aluminum die casting alloys provide better high-temperature performance, retaining strength at temperatures up to 300°C compared to zinc’s limit of around 100°C. Aluminum offers superior corrosion resistance in harsh environments without additional coatings, making it better suited for outdoor applications. Zinc die casting materials have higher density (6.6–6.8 g/cm³) than aluminum (2.7 g/cm³), which can be advantageous for weight distribution in certain components but may increase overall part weight. This property comparison helps identify which material aligns with your application’s functional requirements.

Cost Efficiency Analysis: Zinc Die Casting vs. Aluminum

Cost efficiency differs significantly between zinc die casting and aluminum, impacting long-term production economics. Zinc die casting requires higher initial tooling investment due to its higher melting temperature 模具 requirements, but offers lower per-unit costs at high volumes. The faster cycle times of zinc die casting (15–60 seconds) compared to aluminum (30–90 seconds) increase throughput, spreading fixed costs across more units.

Aluminum has lower raw material costs per kilogram, but its lower density means more volume is needed for equivalent strength, often eliminating material cost advantages. Zinc die casting’s near-net-shape capability reduces secondary machining by 30–50% compared to aluminum, which often requires additional processing for complex parts. For volumes under 10,000 units, aluminum may offer better cost efficiency due to lower tooling expenses, while zinc die casting becomes more economical for higher production runs. This cost analysis helps align your choice with production volume and budget constraints.

Design Flexibility: Zinc Die Casting Capabilities vs. Aluminum

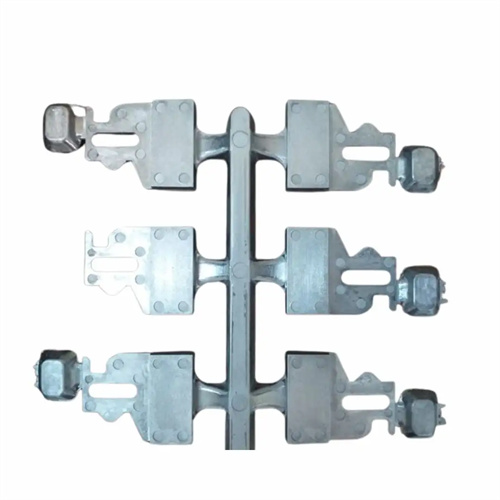

Design flexibility varies between zinc die casting and aluminum, influencing component geometry possibilities. Zinc die casting excels at producing intricate features with fine details, undercuts, and complex internal passages due to its superior fluidity. We regularly achieve wall thicknesses as thin as 0.5 mm in zinc die casting, with sharp reproduction of threads, textures, and decorative elements that require extensive machining in aluminum.

Aluminum die casting offers better suitability for larger components, with maximum part sizes typically 30–50% larger than practical for zinc die casting. Aluminum’s higher strength at elevated temperatures allows thinner walls in heat-exposed applications, balancing weight and performance. Zinc die casting enables greater design consolidation, replacing 3–4 aluminum parts with a single component due to its ability to integrate more features. This design flexibility comparison helps match material capabilities with your component’s geometric complexity and size requirements.

Application Suitability: When to Choose Zinc Die Casting Over Aluminum

Certain applications benefit more from zinc die casting than aluminum, based on functional requirements. Zinc die casting is ideal for small, precision components like consumer electronics housings, where its EMI shielding properties and fine detail reproduction enhance performance and aesthetics. We recommend zinc for parts requiring excellent dimensional stability, such as automotive sensors and medical device components, where tight tolerances (±0.02 mm) are critical.

Aluminum die casting suits larger structural components like automotive chassis parts and heat sinks, where its lightweight properties and high-temperature resistance provide advantages. Outdoor equipment and marine applications often prefer aluminum for its natural corrosion resistance. Zinc die casting excels in components with moving parts—such as hinges and gears—due to its superior wear resistance and damping properties. Identifying your application’s specific demands helps determine whether zinc die casting or aluminum better meets performance needs.

Performance Characteristics: Zinc Die Casting vs. Aluminum in Use

In-service performance differs between zinc die casting and aluminum, affecting long-term reliability. Zinc die casting components offer superior vibration damping, reducing noise in mechanical assemblies compared to stiffer aluminum parts. This property makes zinc ideal for handheld tools and consumer electronics where user comfort is important. Zinc’s higher density provides better impact resistance in small components, withstanding drops and shocks common in portable devices.

Aluminum die casting delivers better thermal conductivity (100–200 W/m·K) compared to zinc (100–120 W/m·K), making it superior for heat-dissipating components like LED heat sinks. Aluminum maintains structural integrity at higher operating temperatures, suitable for engine compartments and industrial machinery. Zinc die casting’s galvanic properties protect against corrosion in multi-material assemblies, acting as a sacrificial anode to protect steel components. Evaluating these performance characteristics ensures your chosen material maintains functionality throughout the product lifecycle.

Sustainability and Recycling Considerations: Zinc Die Casting vs. Aluminum

Sustainability factors play an increasing role in choosing between zinc die casting and aluminum. Both materials are highly recyclable, but zinc requires only 5% of the energy for recycling compared to primary production, versus 5% for aluminum recycling. Our closed-loop recycling systems for zinc die casting achieve 95% material recovery, with recycled zinc maintaining equivalent properties to virgin material.

Aluminum’s lighter weight reduces transportation energy requirements, benefiting overall product lifecycle emissions. Aluminum die casting produces less material waste in large components due to its lower density, while zinc minimizes waste in small, complex parts through better material utilization. Both materials support circular economy models, but zinc die casting’s higher recycling efficiency and lower processing energy give it a slight sustainability edge. Considering these factors helps align your material choice with environmental goals.