Copper alloy die casting performance and other characteristics

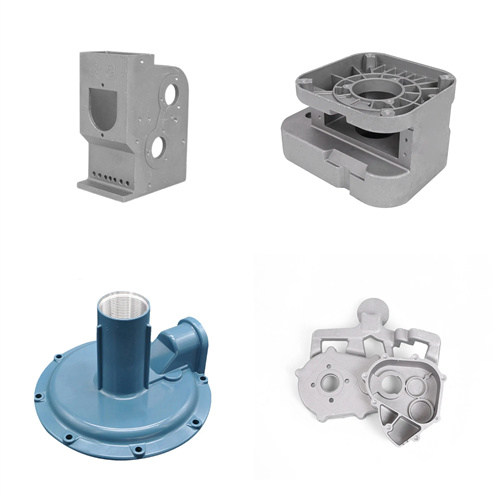

Copper alloys, as an important metal material, are widely used in the die-casting field, and their die-casting performance and other characteristics have attracted much attention in the industry. Copper alloys have excellent electrical and thermal conductivity, corrosion resistance, and mechanical properties, which make them irreplaceable in high-end fields such as aerospace, automotive manufacturing, and electronic appliances. However, the die-casting performance of copper alloys is relatively complex and is affected by many factors, such as the chemical composition of the alloy, die-casting process parameters, and mold design. A deeper understanding of the die-casting performance and other characteristics of copper alloys is of great significance for improving the quality of copper alloy die-castings, reducing production costs, and expanding their application range.

The die-casting properties of copper alloys primarily include fluidity, filling properties, and shrinkage, all of which directly impact the quality of die-cast parts. Fluidity refers to the ability of a molten copper alloy to fill the mold cavity and is one of the key properties required to ensure die-cast parts are formed. Generally speaking, the fluidity of a copper alloy is related to factors such as its chemical composition, temperature, and mold temperature. For example, increasing the zinc content in brass alloys can improve their fluidity, while higher pouring and mold temperatures also help improve fluidity. Fillability refers to the ability of a molten copper alloy to fill every corner of the mold cavity under pressure. Good filling properties ensure the dimensional accuracy and integrity of die-cast parts. Shrinkage refers to the volumetric contraction of a copper alloy during solidification, which affects the dimensional stability and internal quality of die-cast parts. Reasonable mold design and process parameter control are essential to minimize shrinkage defects during production.

In addition to their die-cast properties, copper alloys possess many other excellent properties, such as mechanical properties, corrosion resistance, and electrical and thermal conductivity. Different copper alloys exhibit varying strength, hardness, and toughness in terms of mechanical properties. For example, tin bronze offers high strength and wear resistance, making it suitable for manufacturing components subject to heavy loads and friction. Brass, on the other hand, exhibits excellent plasticity and toughness, making it easy to process and shape. Corrosion resistance is another key characteristic of copper alloys. Copper alloys exhibit excellent corrosion resistance in environments such as air, seawater, and freshwater, leading to their widespread use in shipbuilding, chemical equipment, and other fields. Copper alloys also possess excellent electrical and thermal conductivity. Pure copper exhibits the highest electrical and thermal conductivity, while some alloyed copper alloys maintain certain electrical and thermal conductivity while also possessing high strength and wear resistance, meeting the needs of various applications.

The die-casting performance and other characteristics of copper alloys are closely related to their chemical composition. Different alloying elements have varying effects on the properties of copper alloys. For example, zinc, the primary alloying element in brass, significantly improves the fluidity and strength of copper alloys while reducing costs. Tin, the primary alloying element in tin bronze, enhances the strength, hardness, and wear resistance of copper alloys, but reduces their fluidity. Aluminum improves the strength and corrosion resistance of copper alloys, but excessive aluminum can increase the alloy’s brittleness. Therefore, in production, the chemical composition of copper alloys must be appropriately adjusted to achieve the desired properties based on specific application requirements. Furthermore, the selection of die-casting process parameters also significantly influences the properties of copper alloys. Proper control of parameters such as injection pressure, injection speed, pouring temperature, and mold temperature can effectively improve the die-casting performance of copper alloys and enhance the quality of die-cast parts.

Understanding and mastering the die-casting performance and other characteristics of copper alloys plays an important guiding role in their application in actual production. During the product design stage, it is necessary to reasonably select the alloy grade and die-casting process based on the performance characteristics of the copper alloy to ensure that the product can meet the use requirements. During the production process, by optimizing and controlling the die-casting process parameters, the excellent performance of the copper alloy can be fully utilized, the occurrence of defects can be reduced, and the product qualification rate can be improved. At the same time, in-depth research on the properties of copper alloys will also help to develop new copper alloy materials with higher performance and expand their application in high-end manufacturing. With the continuous development of industrial technology, the quality and performance requirements of copper alloy die-castings are getting higher and higher. Further research on the die-casting performance and other characteristics of copper alloys is of great practical significance for promoting technological progress and industrial upgrading in the die-casting industry.